Inrotech-WeldLogic® is the proprietary software intelligence behind Inrotech’s robotic welding systems, such as the Inrotech-Crawler®. It was developed to automate complex multipass welding with exceptional precision, adaptive planning, consistency, and minimal operator input. This innovation brings advanced robotic logic and adaptability to on-site and large-scale fabrication, where manual welding or traditional automation would otherwise struggle.

At its core, WeldLogic® transforms the robot from a simple motion system into an autonomous welding planner — capable of scanning, analyzing, and executing welding sequences based on the real geometry of each pass on the fly.

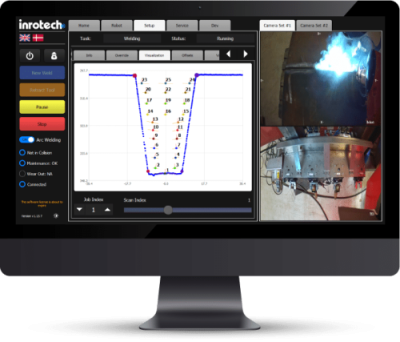

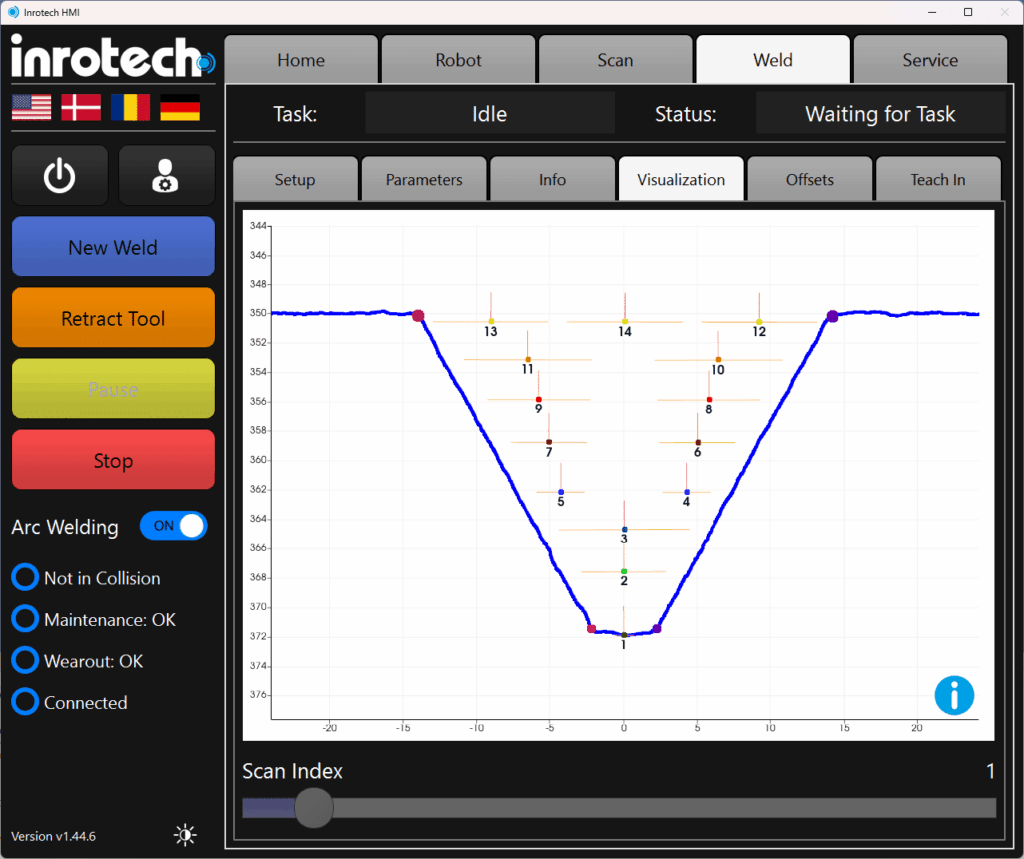

Visualization of live welding metrics

- Weld Pass – Current pass (e.g., 2 of 14) — how many weld layers/passes are completed.

- Layer – Shows which layer is being welded (e.g., 2 of 8).

- Remaining Time – Estimated time left for the ongoing weld sequence.

- Weld Speed – Travel speed of the welding torch (20.9 cm/min in this example).

- Heat Input (1.7 kJ/mm) – Energy applied per millimeter of weld, linked to quality and distortion control.

- Gas Flow (18.8 l/min) – Shielding gas rate — ensures proper gas coverage.

- Temperature (134.76 °C) – Real-time sensor feedback from the weld environment.

The WeldPlanner: The Brain Behind Welding Automation

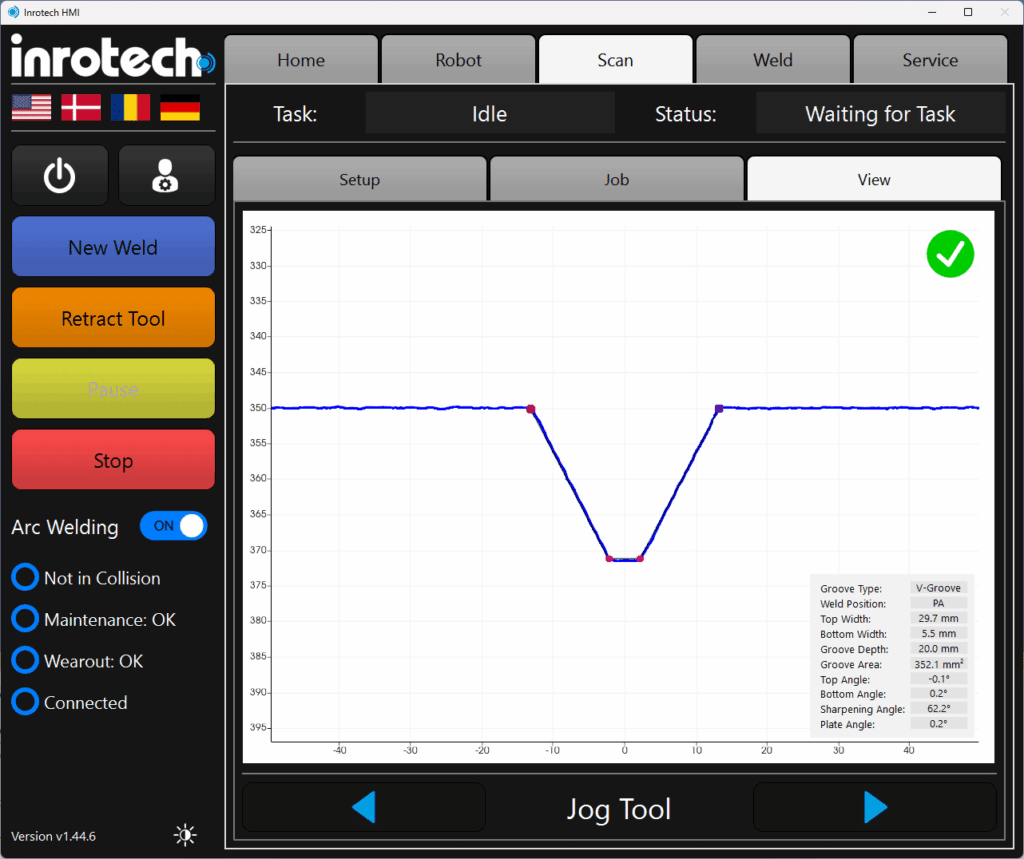

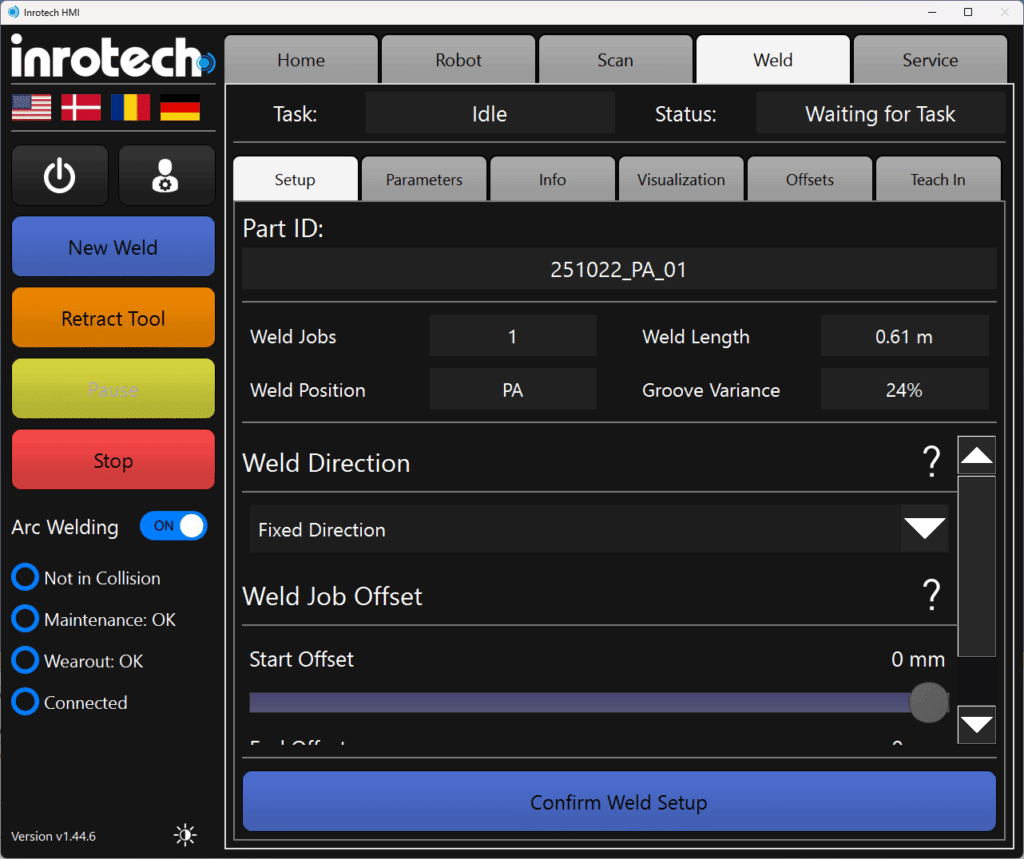

Once the operator initiates a new welding job via the intuitive tablet HMI, the system’s laser scanner automatically measures and identifies the actual groove geometry. The WeldPlanner — the central computational module of Inrotech-WeldLogic™ — processes this scanned data and calculates all relevant welding parameters.

These include:

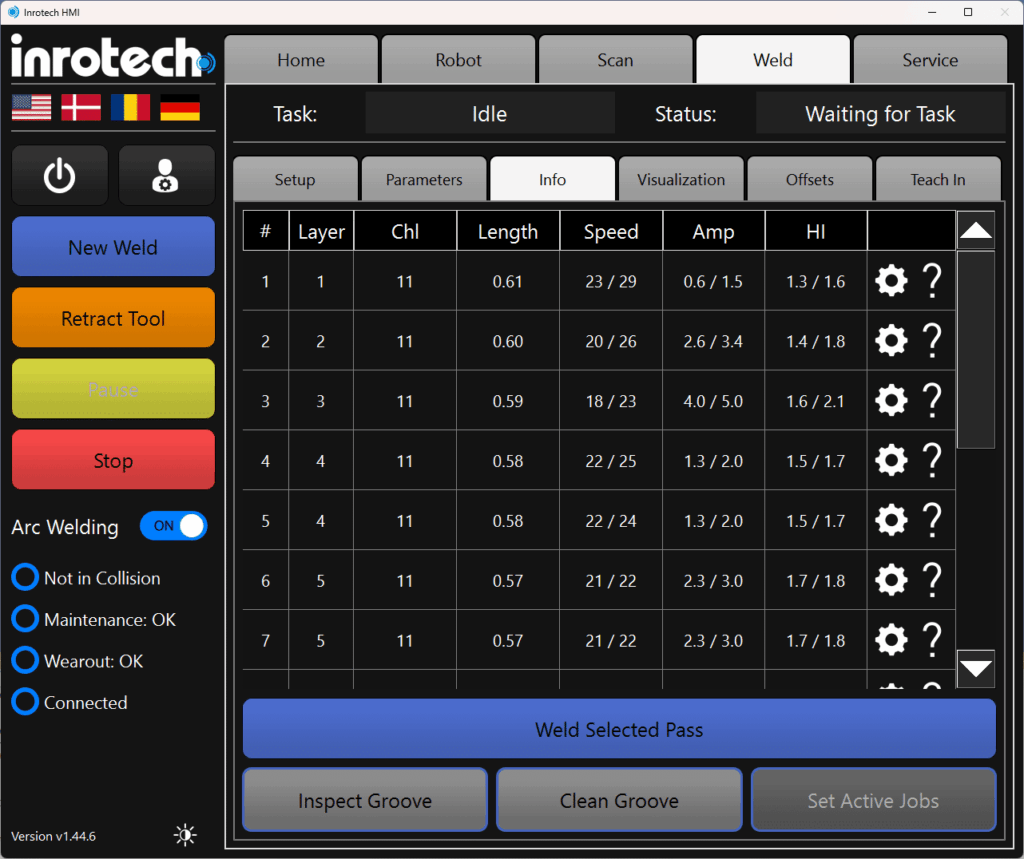

- Number and location of passes

- Layer heights, weaving patterns and torch angle

- Welding speeds, currents, and voltages

- Adaptive parameter adjustments based on groove position, tolerance variations

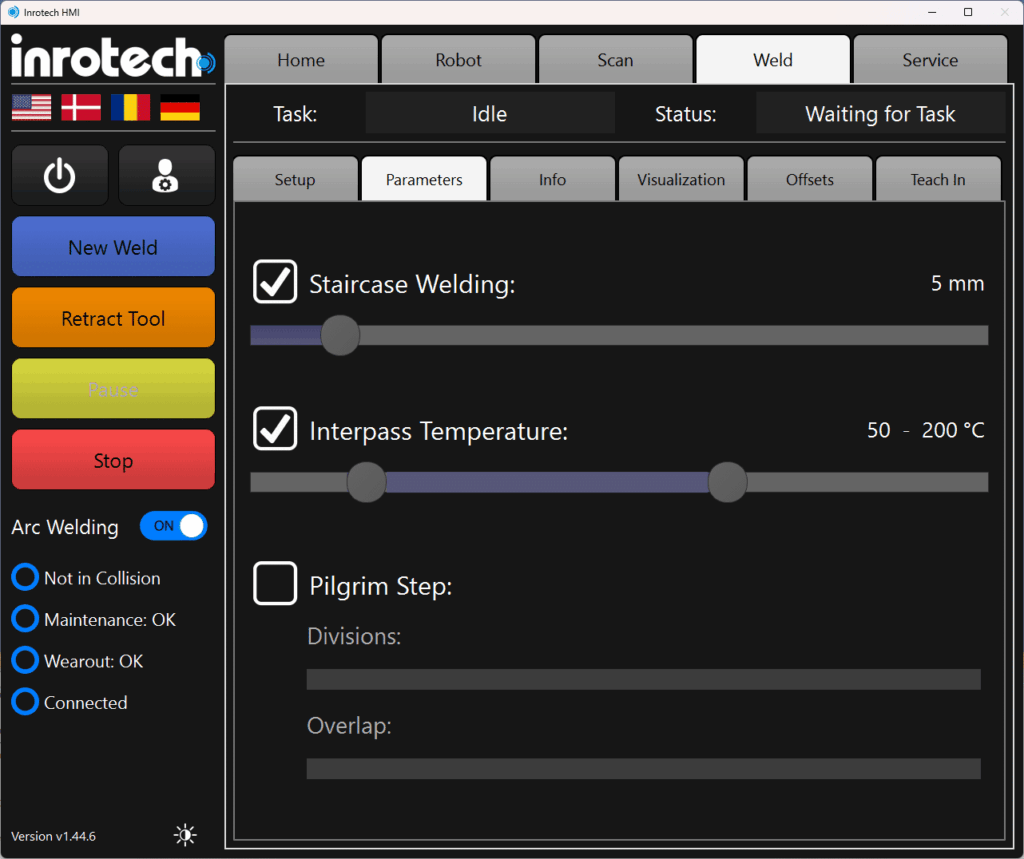

The system allows the robot to react dynamically to real-world conditions, ensuring uniform weld quality and repeatability — even when dealing with irregular or large-scale structures such as ship hull sections, heavy plates, and curved assemblies.

Minimal Input, Maximum Intelligence

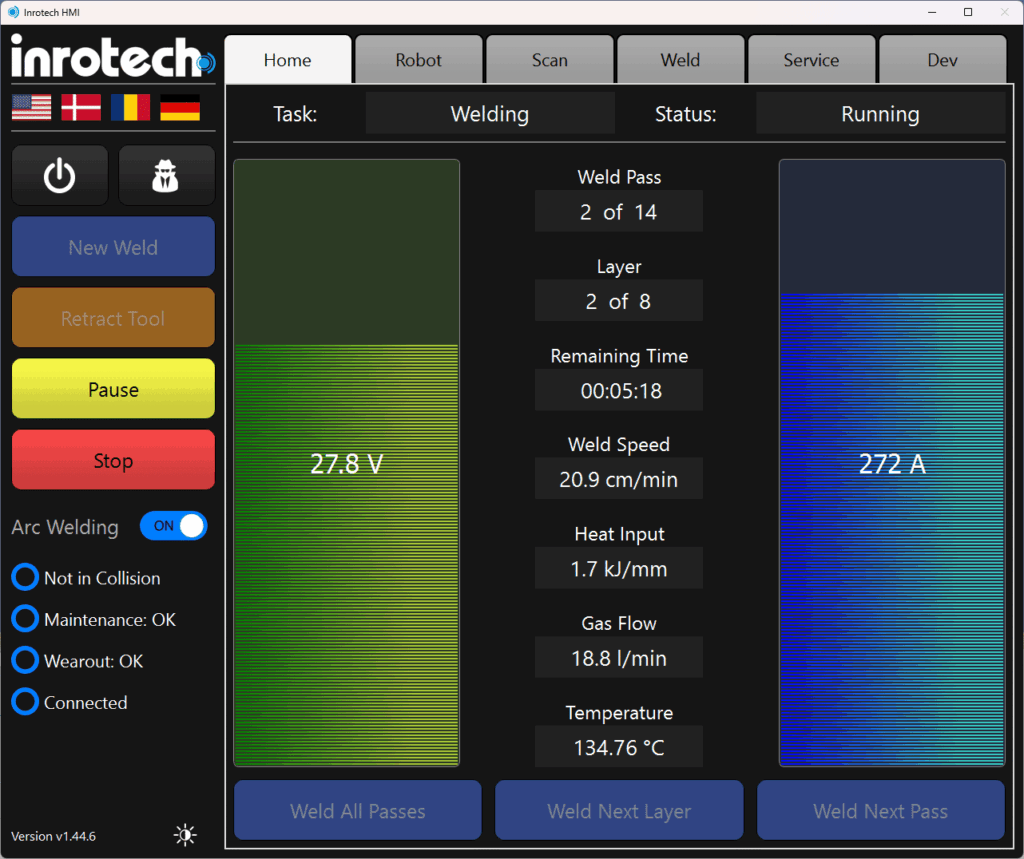

The operator’s role is intentionally simplified. Before startup, the user only needs to provide a few basic inputs such as:

- Thickness and Groove type (e.g. V, half-V, or narrow groove)

- Groove orientation (Flat, inner circle, outside circle)

- Wire and gas selection

After this, the Inrotech-WeldLogic® system performs the rest. The robot scans the joint, plans the sequence, and begins welding autonomously. This ease of use allows a single operator to supervise multiple Inrotech-Crawler® units simultaneously, significantly increasing productivity and reducing labor costs.

Integration of Sensors and Smart Tools

The WeldLogic® system relies on a combination of advanced sensing technologies integrated into Inrotech’s custom multi-tool machine. This tool combines:

- A 2D laser scanner from Micro Epsilon for high-accuracy joint mapping

- A temperature sensor for preheat and interpass measurement

- A water-cooled welding torch from Abicor Binzel

- A pulse deslagging unit for automatic slag removal

- A gas monitoring system for real-time control of shielding gas flow and pressure

These sensors feed real-world data directly back into WeldLogic®, enabling continuous process control and adaptive parameter correction throughout the weld.

From Scanning to Execution

After scanning, the WeldPlanner creates a detailed weld map of the groove. During operation, the system follows a repeatable sequence:

- Measure preheat/interpass temperature

- Execute weld pass

- Clean torch using compressed air

- Pulse deslagging and re-scan of groove

- Automatic adjustment of next pass

Why this process is critical

In advanced welding applications, particularly for heavy-plate and multi-pass joints, precision and repeatability are vital. Every weld pass affects the next: temperature, slag residue, groove geometry, and deposition rate must all be monitored and controlled.

The Inrotech-WeldLogic® sequence eliminates these risks by providing real-time scanning, automated cleaning, and adaptive recalculation between each pass. By re-scanning after every deposited layer, the system updates the weld geometry and corrects for even small deviations caused by heat distortion or filler accumulation.

Efficiency, Quality, and Repeatability

WeldLogic® technology brings measurable benefits across productivity and quality metrics:

- Time savings: Automated planning and execution reduce setup time dramatically.

- Quality assurance: Every pass is planned according to exact geometry, ensuring compliance with the clients WPS parameters and minimizing human error.

- Process consistency: Intelligent monitoring and parameter adaptation maintain uniform quality over long welds and complex geometries.

- Operational simplicity: No offline programming or robot teaching required.

The Inrotech-Crawler®, combined with Inrotech’s robust mechanical systems — lightweight titanium rails, a collaborative UR3 robot arm, and a Lincoln Electric power source — harnesses WeldLogic® to deliver a portable yet industrial-grade welding solution perfectly suited for shipyards, offshore structures, and heavy fabrication environments.

Inrotech-WeldLogic® represents a breakthrough in autonomous welding technology. By combining intelligent scanning, automated planning, and adaptive execution, it bridges the gap between flexible robotic automation and the demanding reality of large-scale on-site welding.

The result is faster, smarter, and safer welding — with precision that rivals the factory floor, anywhere